Product Categories

Focus on Textile Chemicals Industry

Textile Chemicals Specialist

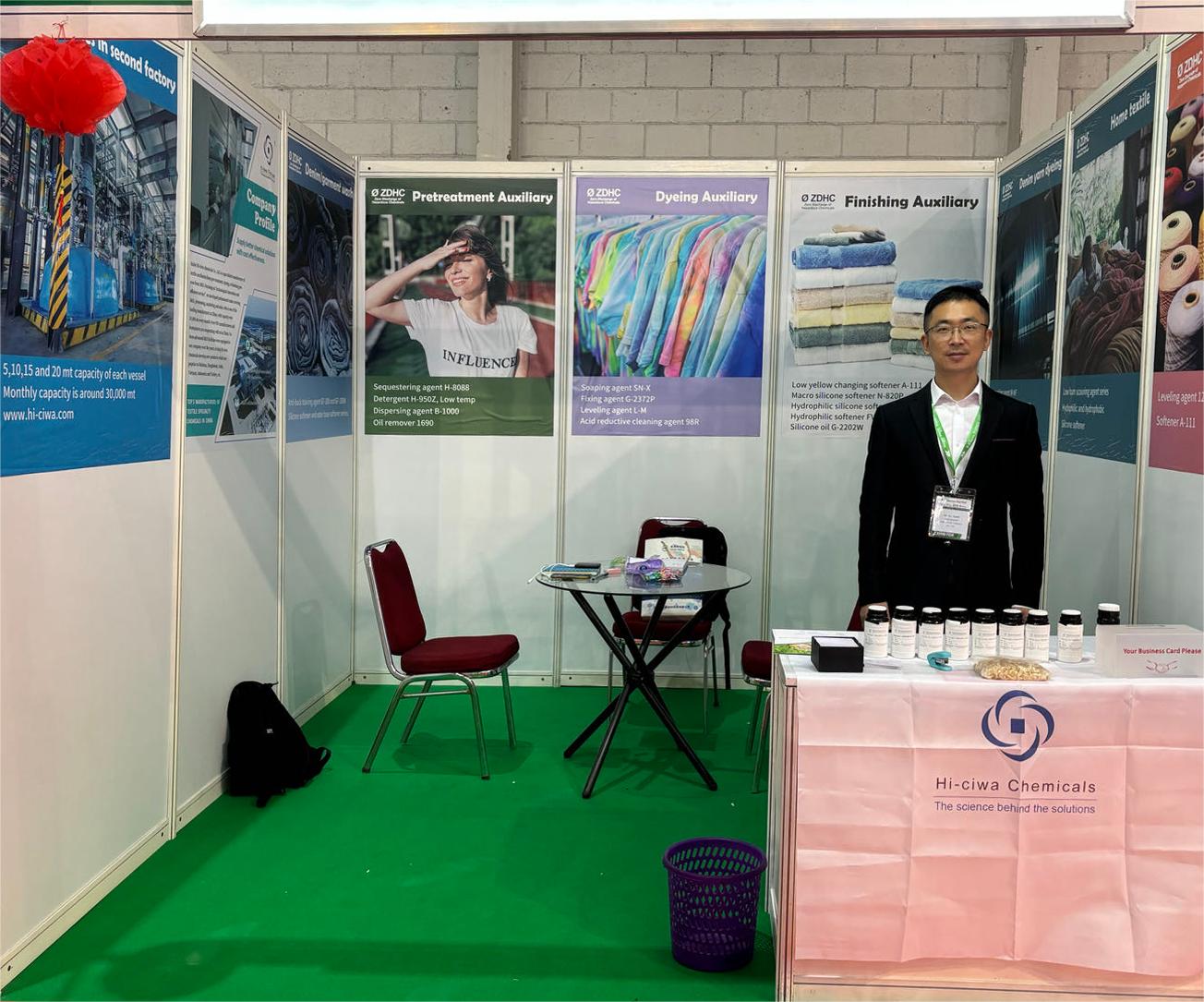

Hi-ciwa is a leading manufacturer of textile chemicals from pretreatment through finishing, such as: scouring agent, oil-remove agent, soaping agent, fixing agent, leveling agent, rub fastness improver, anti-back staining agent, polyester hydrophilic softener, cotton softener paste and silicone oil, etc. Main customer group are dyeing and finishing factories. Besides, we also make raw materials like polyethylene glycol monooleate 400MO and 600MO, N-alkyl phthalimide and acid regulation (ethylene glycol diformate).

Hi-ciwa Mfg's core business is textile specialty chemicals

We rank No.1 supplier to domestic textile chemicals agents.

11 2024-03

fabric surface smooth, no fluff, fiber, yarn parallel, flat, fabric surface directional reflective light ability, reflective light intensity, fabric gloss is strong. Otherwise it's dim.

11 2024-03

In recent years, with the development of science and technology, the types of textile products have become diverse. Modern people are increasingly pursuing multi-functional textiles, the pursuit of cleanliness and comfort of the living environment. The antibacterial health processing is one of the more rapid development and maturity. The antibacterial finishing of fabric began in the 1940s, and this fabric has been applied to hospital, hotel, family bed sheets, quilt covers, blankets, napkins, towels, shoe lining cloth, sand release, curtain cloth, medical professional clothing, bandages and gauze, food and service industry work clothes, military clothing and so on. Antibacterial sanitary finishing is called "antibacterial finishing" and "antimicrobial finishing" in the United States and other countries; In Japan it is called "antibacterial and deodorant processing".

04 2024-03

Let's learn about the dyeing, finishing, and inspection knowledge of fabrics. The selection of dyeing and finishing process flow is mainly based on the variety, specifications, and finished product requirements of the fabric, which can be divided into pre-treatment, dyeing, etc

26 2024-02

The research about non-foaming soap HX show that the ideal process of non-foaming soap HX can achieve the ideal soap fastness and dry and wet friction fastness under the condition of 05g/L holding at 95℃ for 20min.

30 2024-01

What surfactants are used to reduce the height of the foam